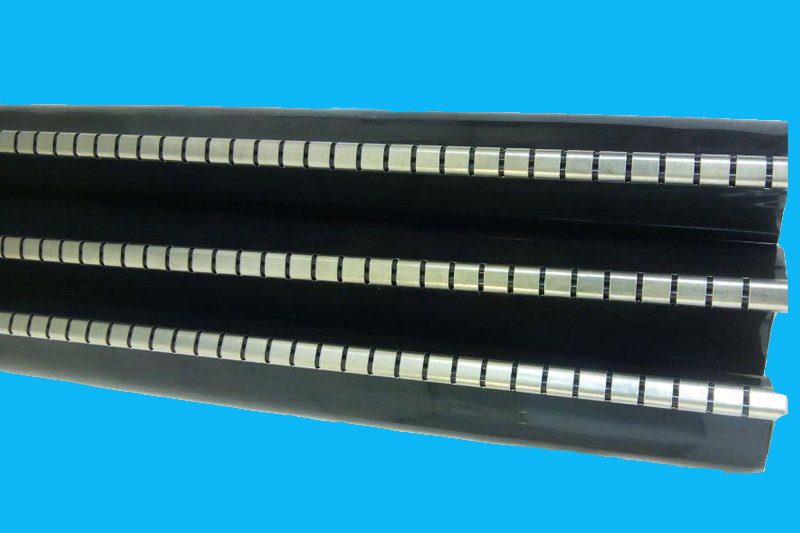

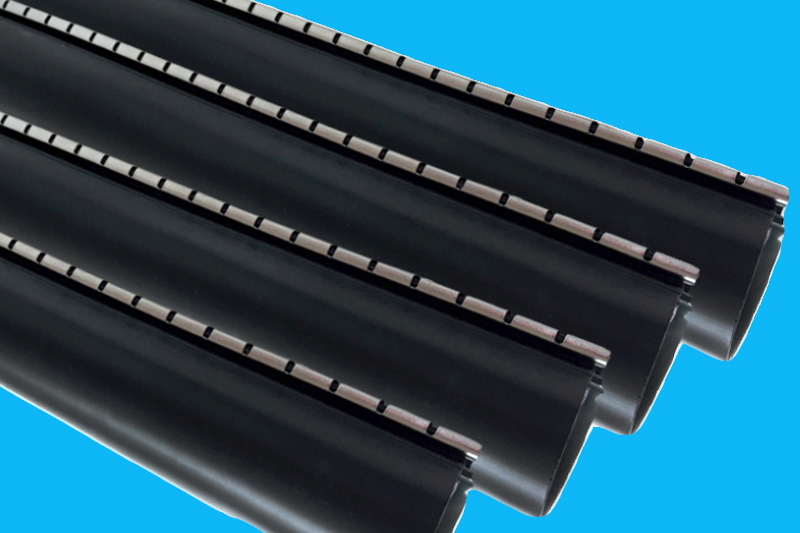

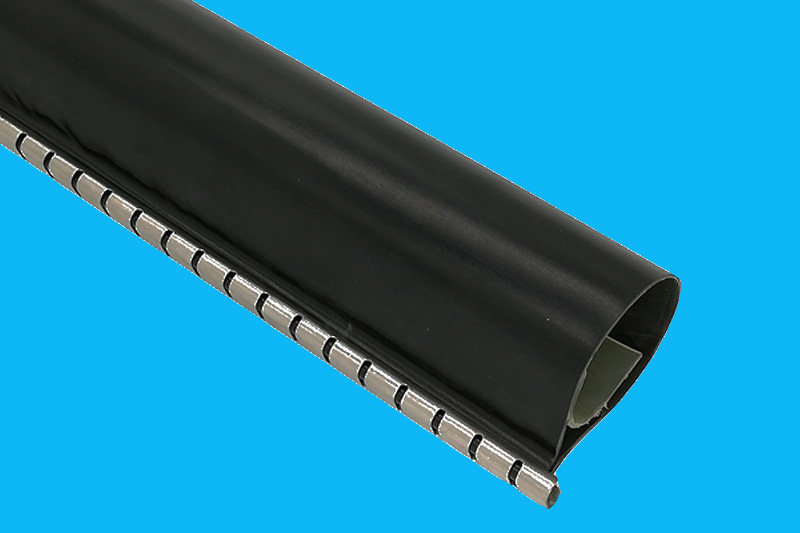

Zippered heat shrink tubing/cable patch

Cable repair piece is a kind of covered sheath repair sleeve, which is the common name for longitudinally wrapped reinforced heat shrink sleeve for non-pressure protection.

- Shrink Ratio:

- 3:1

- Standard Color:

- Black

- Withstand Voltage Level:

- 1-35KV

- Features

- Quick repair without cutting the cable, sealed and waterproof

Cable repair piece is a kind of covered sheath repair sleeve, which is the common name for longitudinally wrapped reinforced heat shrink sleeve for non-pressure protection. Cable covering sheets are also called cable repair sheets, zipper heat shrink tubes, and heat shrinkable cable connection outer sheaths. The internal coating of sealant can effectively seal and waterproof. The construction is simple, the size range is wide, and it is suitable for various occasions. The outer layer of the product is sprayed with temperature-indicating paint. When heated, the temperature-indicating paint changes color, indicating that the shrinkage temperature has been reached. It is used to quickly repair the damage to the cable sheath without cutting the cable to make it insulated and sealed. It can reduce installation costs by 80%, and there is no need to stop work during installation. The inner surface glue coating process is moisture-proof, and the innovative process facilitates quick and convenient installation.

|

Performance technical indicators of zipper heat shrink tubing |

||

|

characteristic |

Test Methods |

Performance |

|

tensile strength |

ASTM-D 2671 |

≥13MPa |

|

Elongation at break |

ASTM-D 2671 |

≥300% |

|

Tensile strength after aging |

ASTM-D-2671/120℃,168hrs |

≥11MPa |

|

Elongation at break after aging |

ASTM-D-2671/120℃,168hrs |

≥250% |

|

Breakdown strength |

IEC 243 |

≥15kV/mm |

|

Volume resistivity |

ASTM-D-2303 |

≥1×1013Ω ·cm |

|

Longitudinal shrinkage |

- |

≤10% |

|

Deviation rate |

ASTM-D-267 |

≤30% |

|

Zipper type heat shrink tube (cable repair piece) specification sheet |

|||||

|

Specification model |

Inner diameter (mm) |

Wall thickness (mm) |

Standard length (mm) |

||

|

Before contraction (≥) |

After shrinkage (≤) |

After complete contraction |

|||

|

Ф 30 |

30 |

13 |

1.3±0.2 |

3.9±0.2 |

900 |

|

Ф 40 |

40 |

13 |

1.2±0.2 |

3.9±0.2 |

900 |

|

Ф 50 |

50 |

16 |

1.3±0.2 |

3.9±0.2 |

900 |

|

Ф 65 |

65 |

23 |

1.3±0.2 |

3.9±0.2 |

900 |

|

Ф 80 |

80 |

33 |

1.3±0.2 |

3.9±0.2 |

900 |

|

Ф 100 |

100 |

33 |

1.4±0.2 |

4.1±0.2 |

900 |

|

Ф 120 |

120 |

41 |

1.4±0.2 |

4.1±0.2 |

900 |

|

Ф 150 |

150 |

51 |

1.4±0.2 |

4.1±0.2 |

900 |

|

Ф 160 |

160 |

51 |

1.2±0.2 |

4.1±0.2 |

900 |

|

Ф 170 |

170 |

51 |

1.1±0.2 |

4.1±0.2 |

400 |

|

Ф 190 |

190 |

85 |

1.0±0.2 |

2.3±0.2 |

400 |

Length can be produced as required